How It Works

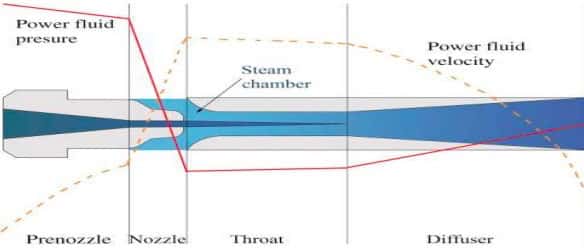

Jet Pumps function by utilizing the Venturi effect. The Venturi effect is a special case of Bernoulli’s principle which states that as fluid flows through a pipe with a constriction in it, the fluid must speed up in the restriction, reducing its pressure and producing a vacuum via the Bernoulli Effect. This vacuum is what brings formation fluids into the jet pump and to the surface.

Jet Pump Operation

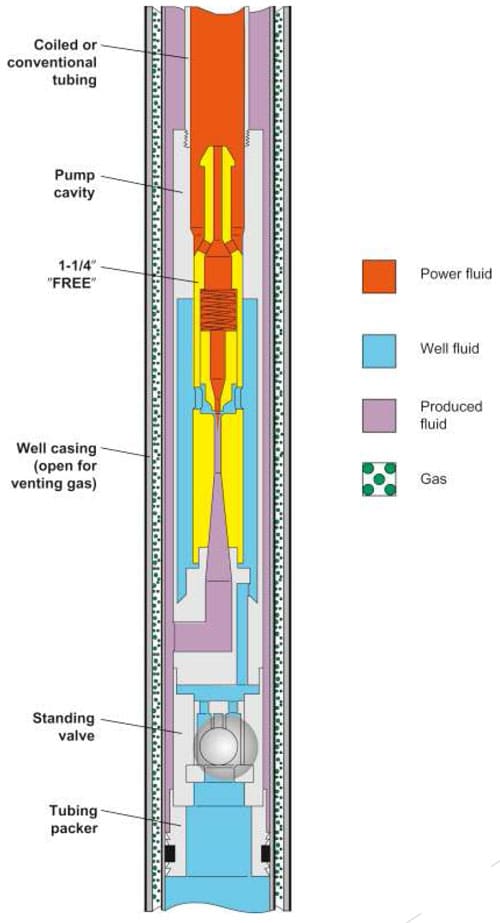

The unique design allows for easy retrieval of a jet pump from straight well bores as well as deviated and horizontal wells. Retrieval of the jet pump for repair or optimization is done by reversing the fluid flow using the surface valves at the well head or manifold, no work over or wire line unit is required.

The pump utilizes the momentum of one fluid to move another fluid.

The pump consists of:

- A nozzle to increase the velocity and decrease the pressure of the power fluid.

- An intake where drawdown directs the produced fluid into the high velocity jet.

- A mixing tube (throat) where the power fluid encounters the produced fluid.

- A diffuser where the velocity of the mixed stream is decreased, pressure is increased, and the fluid is returned to surface.

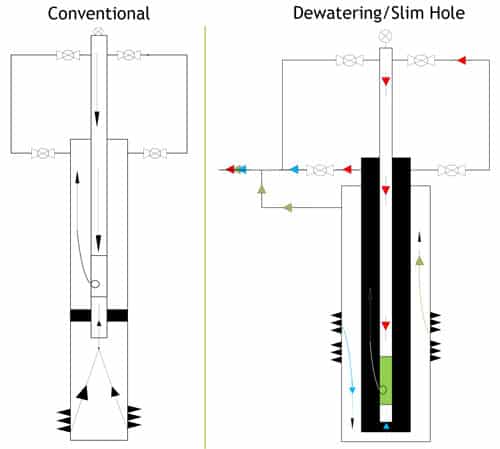

Jet Pump Applications

Typical applications of the jet pump include:

- Conventional Oil & Gas Production

- Gas Well Dewatering

- Bad Casing

- High Volume Frac Flow Back

- Deviated Wells

- Slim-hole Wells

- Reverse Flow Casing Injection

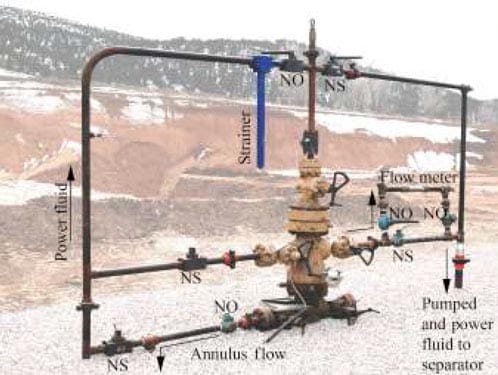

Well Head Configuration

The unique design allows for easy retrieval of a jet pump from straight well bores as well as deviated and horizontal wells. Retrieval of the jet pump for repair or optimization is done by reversing the fluid flow using the surface valves at the well head or manifold, no work over or wire line unit is required.

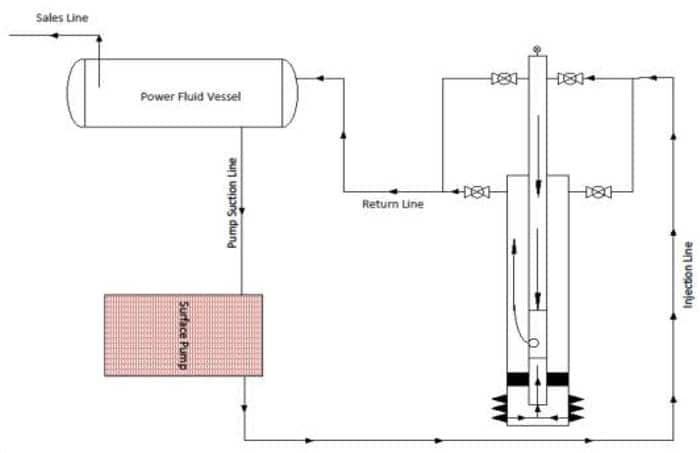

Surface Schematic

Installation